MacBook Air (early 2020) configuration: i7/16GB/1TB

TL;DR: Filling the sub-millimetre gap between the heat sink and processor with a copper shim improves performance by up to 20%.

Date of original mod: 30 April 2020

MacRumors: Post 984, Post 998, Post 1003

Below are rough measurements of the processor and heat sink, which will be useful for knowing how big of a copper shim to use.

I didn't have shims in the correct planar size, so I had to cut one of my 15x15 mm shims to get enough length. A width of 15 mm is enough to cover the CPU and GPU.

I spread a thin layer of Arctic MX-4 thermal paste onto the heat sink and "pasted" the shims on. This way, I know that the shims will be positioned properly when I lay the heat sink back onto the processor (with another layer of thermal paste).

The first thing I noticed was that the CPU temperature was much less sensitive to changes in CPU load, which might mean that the fans switch between on/off less often. In the screenshots below, the temperature rises gradually, whereas before it would shoot up much steeper.

After a 15 min stress test using Intel Power Gadget, the temperatures around the case appear normal.

I don't remember if my MacBook Air was originally able to sustain max Turbo Boost on a single core.

TL;DR: Filling the sub-millimetre gap between the heat sink and processor with a copper shim improves performance by up to 20%.

Date of original mod: 30 April 2020

MacRumors: Post 984, Post 998, Post 1003

Visual Context

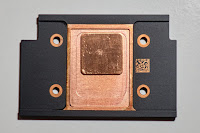

The photos below provide an overview of what we're dealing with. The heat sink is made of aluminium and the underside has a copper coating. A dark, thick, gritty thermal paste has been used.

Note: bottom case screws are Pentalobe 5 (P5) and heat sink screws are Torx 4 (T4).

After cleaning the thermal paste off the processor and heat sink with alcohol wipes, we can see more clearly a shallow cutout in the heat sink's underside, which contributes to the unnecessary gap between the processor and heat sink.

Below are rough measurements of the processor and heat sink, which will be useful for knowing how big of a copper shim to use.

The "2 cm" marking is aligned to the inner edge of the heatsink padding:

I should have aligned the "3 cm" marking to the inner edge of the heat sink padding:

The "2 cm" marking is aligned to the long edge of the cutout:

The "3 cm" marking is aligned to the short edge of the cutout:

The heat sink relative to a 15x15 mm copper shim:

Heat Sink Modification

To gauge how thick the shims needed to be, I prototyped some "shims" from paper of various thicknesses. I found that the thickness of a business card was quite good. Unfortunately, the shims I bought were 0.6 mm thick, so I had to spend a few hours slowly filing them down. In the end, they were still thicker than I needed, but at least thin enough for me to screw the heat sink down. The heat sink screws are incredibly small and the threaded ends are only around 2 mm in length.I didn't have shims in the correct planar size, so I had to cut one of my 15x15 mm shims to get enough length. A width of 15 mm is enough to cover the CPU and GPU.

I spread a thin layer of Arctic MX-4 thermal paste onto the heat sink and "pasted" the shims on. This way, I know that the shims will be positioned properly when I lay the heat sink back onto the processor (with another layer of thermal paste).

Results

To evaluate the success of the combined wind channel and heat sink modifications, I ran the tests in Intel Power Gadget 3.7.0, Geekbench 5.1.0, and Cinebench R20. I used the same set up as before, but also waited for the CPU to cool down to around 42℃ before running the next benchmark. Each benchmark was executed at least three times and I report the average.The first thing I noticed was that the CPU temperature was much less sensitive to changes in CPU load, which might mean that the fans switch between on/off less often. In the screenshots below, the temperature rises gradually, whereas before it would shoot up much steeper.

After a 15 min stress test using Intel Power Gadget, the temperatures around the case appear normal.

Geekbench 5

The single-core and graphics performance are only slightly better. I think it is because thermal throttling did not happen much for those tests with the original heat sink. Multi-core performance, however, is about 20% higher. Click on a "Mod" result to view the best that I got.| Test Type | Original (Points) | Mod (Points) | Improvement |

|---|---|---|---|

| CPU (Single-core) | 1,214 | 1,271 | 4.8% |

| CPU (Multi-core) | 2,992 | 3,666 | 22.5% |

| Compute (OpenCL) | 3,825 | 3,944 | 3.1% |

| Compute (Metal) | 4,285 | 4,491 | 4.8% |

Cinebench R20

Single-core and multi-core performance both improved by about the same amount, unlike the large performance improvement gap seen with Geekbench.| Test Type | Original (Points) | Mod (Points) | Improvement |

|---|---|---|---|

| CPU (Single-core) | 353 | 390 | 10.5% |

| CPU (Multi-core) | 979 | 1,110 | 13.5% |

| MP Ratio | 2.77 | 2.84 | 2.7% |

Intel Power Gadget 3.7.0

Lastly, I did some plain-old stress tests, which show about 20% improvement in sustained CPU and GPU performance.| Test Type | Original (GHz) | Mod (GHz) | Improvement |

|---|---|---|---|

| CPU (All Thread Frequency, Scalar) | 2.25 | 2.70 | 20.0% |

| CPU (All Thread Frequency, AVX-256) | 2.12 | 2.59 | 22.2% |

| CPU (All Thread Frequency, AVX-512) | 2.00 | 2.40 | 20.0% |

| Intel Graphics Test (Max Frequency) | 0.90 | 1.10 | 22.2% |

I don't remember if my MacBook Air was originally able to sustain max Turbo Boost on a single core.